Yohann BOURCELOT

Offshore Technician / Mechanic / Navigator

50 years old

Driving License

Employed

Open to opportunities

Technician manufacturing polyurethane and PVC conveyor belts

Reveyron

Since October 2017

- Manufacturer of light conveyor belts and curved belt conveyors

Founded in 1926, the Reveyron company has seen its know-how progressively evolve from technical weaving to the design and manufacture of conveyor belts, then to curved belt conveyors. Today, it is supported by a team of 50 competent people who provide daily attentive listening, quality service and technical advice to meet your requirements.

Reveyron anticipates and adapts to the expectations of its customers, in various industries such as: Food, Agriculture, Chemistry, Pharmacy, Automotive, Metallurgy, Plastics, Recycling, Textile, Wine, Packaging and Packaging, Laundry, Wood & Furniture, Paper and Cardboard, Cosmetics, Printing, Logistics, Building & Construction Materials ...

The company has a modern and flexible production unit, dedicated to the manufacture of polyurethane & PVC light conveyor belts, as well as a workshop equipped with a large number of machines making customized conveyor belts. In addition, it has a mechanical and assembly workshop dedicated to the manufacture of conveyor belts. - Assigned to continuous installation, my job is to put guides and profiles on our customer’s conveyor belts.

- Guides are used for the smooth running of conveyor belts in case of transverse forces.

- Profiles can replace sidewalls (when conveying products in bulk) and can be used as guidance for single or double inflection conveyors.

- In such a context, I prepare, sand and place guides and other fittings on the conveyor belts. I also indicate where to place fittings on the conveyor belts and I put cleats with a high frequency welding-blanking machine.

Navigator on Seismic Vessel (more than 16 years in Seismic)

« CGG » Compagnie Générale de Géophysique

October 2011

to January 2016

Full-time

International spots

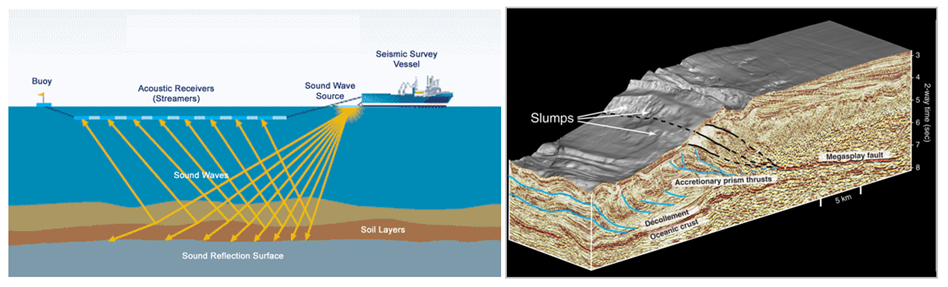

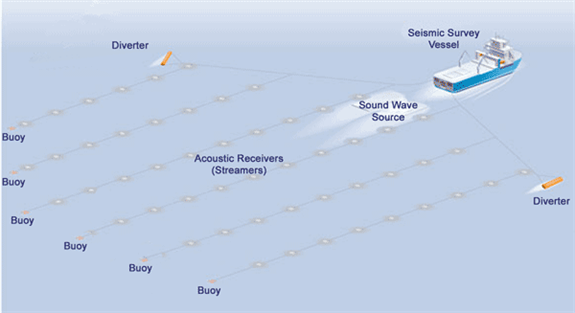

- CGG is a leader in cutting-edge geoscience. The company have achieved leadership through a strong focus on innovation and a commitment to delivering the best sustainable solutions to their clients' energy challenges. They bring their clients a unique range of technologies, services and equipment designed to acquire extremely precise data and images of the Earth's subsurface. The firm also provides state-of-the-art software and services for analyzing that data and developing a deeper understanding of the subsurface for exploration, production and optimization of oil and gas reservoirs.

CGG employs more than 9 000 people in 50 countries. The company is listed on Euronext Paris and the New York Stock Exchange. - Contact with clients and synthesis of their needs.

- Implementation of navigation procedures.

- Streamers remote control (regarding their depth, but also their gaps while being careful about not tangling them when the vessel bends).

- Moves with a MO Boat (Man Overboard Boat) during the guide-planes changes of the streamers, as well as the batteries on the tail and head buoys at sea. Cleaning of streamers at sea and replacement of defective parts.

- Vessel navigation in real time and synchronization of the shooting points during the prospecting phases.

- October 201: CGG Neptune Naiad, Seismic Navigator

- November 2012: CGG Géowave Voyager, Seismic Navigator

- January 2013: CGG Pacific Finder, Seismic Navigator

Technician and mechanic source on Seismic Vessel

« CGG » Compagnie Générale de Géophysique

January 2007

to October 2011

Full-time

International spots

- Maintenance of the on-board mechanical Equipment ("geophysic" aspect of the job).

- Source maintenance and deployment (air guns, solenoid valves, boat deck fitting, plastic welding on floats and buoys, other welds).

- General maintenance (high-pressure air circuits, hydraulic system, pumps, generator etc).

- Preparation and deployment at sea of all the device appropriate to geophysics (sources, streamers, tail buoys, head buoys, paravanes deflector…).

- Maintenance and use of MO Boat (Man Overboard Boat) for the streamers' shift guide-birds, as well as the batteries on the tail and head buoys.

- Elaboration and setting of the procedures.

- March 2007 : CGG Orion, Seismic Gun Mechanic

- September 2010 : CGGVéritas Vantage, Seismic Gun Mechanic

Technician & Mechanic source on Seismic Vessel (electromangnetic waves)

Multiwave (Norway)

June 2005

to January 2007

Freelancer

International spots

- Multiwave is a seismic company based at Bergen (Norway)

Multiwave is part of the CGG Group (Groupe of Compagnie Générale de Géophysique). It is a worldwide participant in the oilfield services industry, supplying a wide range of seismic, dealing with oil extraction, gas and production.

In the CGG Group, Multiwave is the competence center for seabed exploration (seismic market in high-growth)

Multiwave owns a worldwide seven boats' fleet (2D vessels and seabed logging boats used for seabed operations) of exploitation. - Maintenance and deployment of positioning beacons.

- Maintenance of the mechanic equipment on boat.

- Source maintenance and deployment (Generator of electromagnetic wave and its electrodes).

- Maintenance and use of crane's hydraulic system.

- Programming of transponders.

- In charge of the electromagnetic wave generator's navigation in order to make it pass above beacons which are spread at the seafloor.

- June 2005 to January 2007 S/V Atlantic Guardian, seismic technician & seismic mechanic

Supervisor for high voltage power station building

«VATECH » Schneider Electrique (Grenoble)

August 2004

to June 2005

Freelancer

International spots

- Supervisor for power station building (High voltage: 400 KV) at Bagdad, more than 20 persons (Irak, Al Amin headquarters, from November 2004 to January 2005).

- Supervisor for power station building (High voltage: 60 KV) in the Hassi Messaoud and the Hassi-H'mel deserts in Algeria, 6 persons (March 2005).

- Supervision of the building construction of the place which shall be used to be a power plant in Saudi Arabia, 4 persons (May 2005).

- In charge of the smooth progress of the assembly of electric power stationd (very high voltage: from 60 to 400 KV).

- Sending of daily reports to the Grenoble office.

- Link between the client and the company.

- Assistant during the dielectric tests phase.

Technician & Mechanic source on Seismic Vessel

« CGG » Compagnie Générale de Géophysique

July 1998

to June 2003

Full-time

International spots

- Maintenance of the mechanic equipement on boat.

- Source maintenance and deployment (air guns, solenoid valves, boat deck fitting, plastic welding on floats and buoys, other welds).

- General maintenance (high-pressure air circuits, hydraulic system, pumps, generator etc).

- Preparation and deployment at sea of all the device appropriate to geophysics (sources, streamers, tail buoys, head buoys, paravanes deflector…).

- Maintenance and use of MO Boat (Man Overboard Boat) for the streamers' shift guide-birds, as well as the batteries on the tail and head buoys.

- Elaboration and setting of the procedures.

- July 1998 : CGG Mistral, Seismic Gun Mechanics

- September 2001 : CGG Harmattan, Seismic Gun Mechanics

- January 2002 : Martin II, Technician Container compressor LMF / Seismic Gun Mechanics

- July 2002 : CGG Mistral, Seismic Gun Mechanics

- February 2003 : CGG Amadeus, Seismic Gun Mechanics

Operator on lathe and milling machine

French Navy

January 1998

to June 1998

Part-time

Toulon

France

- Repair or re-manufacturing of defective parts of ships as vannes, engines, collectors...

Mechanic on the Clemenceau aircraft carrier

French Navy (Toulon)

March 1995

to January 1998

Part-time

International spots

- Maintenance and use of the Aircraft Carrier catapults for the Launching Aircrafts.

- Maintenance of the cooling circuit of the deflectors of G (gravity).

- Launching Aircrafts (Rafales, Crusader, modernized Super Etendard and alizé) as a slinger on the catapult side.

- Operation Salamander: surveillance mission in Ex-Yougoslavie (December 1995).

Equipment of Toulon for the aircraft carrier Clemenceau, the Jean Bart and the Meuse.

Boarding of helicopters (5th RHC) and the French army light aviation as well as other units of the Navy.

At this time, the Aircraft carrier is alone on zone. Start of aerial missions in Bosnia. Presence on zone of the USS AMERICA and of the HMS Illustrious.

Mechanic on classic submarine

French Navy (Lorient)

May 1994

to February 1995

Part-time

International spots

- Submariners school at the submarine base of Lorient, France (Elementary Patent).

- Affectation on a submarine with classic propulsion (called "Ouessant").

- Maintenance of diesel engines of the Submarine, and various mechanics tasks on-board

- In charge of the maintenance of the on-board oxygen system.

- Use and maintenance of the boilling system that makes sea-water drinkable.

- Shift of the submarine's bilge batteries.

VAE (validation of acquired experience), BTS Industrial system maintenance in progress

DAVA de l'Académie de Lyon

Since December 2016

Understand the meaning of any conversation, tv or radio shows, in current contexts, but also in a professional environnement.

Read and write any type of text.

Intervene in all kind of conversations (profesionnal or not, face to face, on the phone).

Read and write any type of text.

Intervene in all kind of conversations (profesionnal or not, face to face, on the phone).

Basic Offshore Safety Induction & Emergency Training (OPITO), including HUET plus Emergency Breathing System, Compressed Air Emergency Breathing System (CA-EBS)

Falck, Amsterdam

June 2017

to August 2021

How to survive in sea in case of shipwreck or crash helicopter.

Know how to make the first aid on an injured person.

Know how to make the first aid on an injured person.

• Knowledge of basic notions in project management.

• Master of planning techniques and follow-up of projects.

• Identification of a manager's added value.

• Acquisition of tools and methods to manage a team.

• Efficient communication development while giving a way to the team activity.

• Make one's stakeholders responsible and involved.

• Handle successfully stressfull situations.

• Master of planning techniques and follow-up of projects.

• Identification of a manager's added value.

• Acquisition of tools and methods to manage a team.

• Efficient communication development while giving a way to the team activity.

• Make one's stakeholders responsible and involved.

• Handle successfully stressfull situations.

Training: supervising a high voltage power station building

VATECH (Schneider Electrique) sur Grenoble

August 2004

to November 2004

Training to become a supervisor on high voltage power station buildings (from 60 to 400 KV).

Understand the meaning of any conversation, tv or radio shows, in current contexts, but also in a professional environnement,

Read and write any type of text.

Intervene in all kind of conversations (profesionnal or not, face to face, on the phone)

Be able to introduce oneself and attend a meeting.

Read and write any type of text.

Intervene in all kind of conversations (profesionnal or not, face to face, on the phone)

Be able to introduce oneself and attend a meeting.

Navy course in mechanics

CIN at Saint-Mandrier (France, at the French Navy training center)

April 1994

to May 1994

Affected to a ship, but also on the ground unity, naval mecanics are driving and mantaining the propulsif machine (diesel, steam, gas turbine), refrigerating, hydraulic and pneumatic plants. They are also responsible for the maintenance of heating networks, air conditioning, production and water distribution, but also air under pressure.

French Navy Preparatory School

Lycée Franklin Roosevelt (Reims, France)

September 1993

to March 1994

First year of Bac F1 (level IV)

Diploma of Machining of precision on lathe and milling machine (BEP - CAP)

Lycée professionnel Le Haut du Val

September 1991

to June 1993

The turner-milling machine operator works on a machine with perfectly smooth parts fitting exactly with the ordered size.

On the lathe machine, the tool moves forward on the part. On a milling machine it is the part which moves forward to the tool.

On the parts to be produced, the milling machine operator drills, makes grooves or any other operation according to the order.

On the lathe machine, the tool moves forward on the part. On a milling machine it is the part which moves forward to the tool.

On the parts to be produced, the milling machine operator drills, makes grooves or any other operation according to the order.

- Team management (4 to 20 persons)

- Ability to motivate people/teams

- Constructive conflicts management

- Organisation

- Communication & ability to listen

- Stress management & Self control

- Honesty & integrity

- Flexibility & adaptability

- Empathy

-

Preventive and curative mechanical maintenance

Advanced

-

Project Management

Good

-

Manufacturing machine tools shooting and reaming

Good

-

Arc welding with coated electrode, Blowtorch Oxyacetylen, TIG and MIG & Thermoplastic

Good

-

Electricity

Intermediate

-

Hydraulics and circuit of high-pressure air

Good

-

Windows, Microsoft Pack Office, Power Point, Adobe Acrobat DC, texte, calcul, email, internet....

Good

-

Autocad, Adobe Premiere Pro CC, Adobe After Effects CC, GoPro Studio....

Good

-

English (fluent) (Current level B2)

Good

- Bike

- Ski

- Indoor climbing

- Sport Club Genae at Ecully (France)

- Malaisia, Indonesia, Timor, Viêt-Nam, South of India, Maldives, Kenya, South Africa, Morrocco, Italy, Norway, Mexico, New-Orleans, Jordania, Nova Scotia, Cuba……..

- Indoor and Outdoor design

- Cinema

- Creative activities with my kids

- DIY